New Research: 3D Printed Bone Implants that Release Antibiotics

Researchers from Zhejiang University and Taizhou University have developed 3D printed bone fixation implants that combine structural support with targeted antibiotic delivery.

Led by Liwen Zhang, the team used stereolithography (SLA) to fabricate customized bone nails made from dental resin composites infused with ceftriaxone sodium, an antibiotic commonly used to prevent infections during surgery.

Orthopaedic implants used in bone repair are often limited by poor biocompatibility or a lack of therapeutic function. Published in Nature Scientific Reports, this study addresses both issues by introducing an implant that not only supports healing bone but also helps control infection at the site. Fabricated using commercially available Anycubic Photon and Mono X 3D printers, the design highlights the potential of accessible, customizable manufacturing in medical settings.

To build the implants, the team first developed a custom resin formulation. They blended ethoxylated bisphenol A dimethacrylate (BPA 2 EOD MA) with triethylene glycol dimethacrylate (TEGDMA) in a 7:3 ratio, an optimal mix for strength and printability. The formulation included 1 % TPO photoinitiator to enable UV curing.

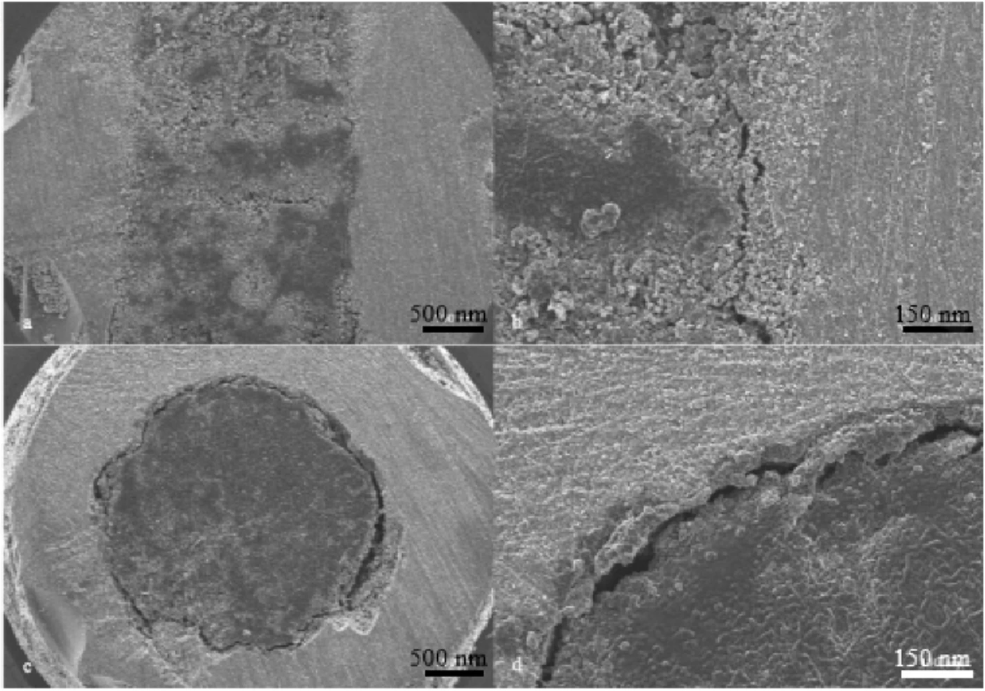

Using SolidWorks software, the researchers designed the implants and printed them at a resolution of 50 microns, layer by layer. After printing, the parts were post - cured to ensure full hardening. Electron microscope images showed a dense, solid outer layer for mechanical strength, while the inside remained porous, perfect for storing and slowly releasing the antibiotic.

Tests revealed that the implants could handle forces within the range required for non - load - bearing bone repairs, such as in the face or skull. The implants were also tested with three different antibiotic concentrations (1 %, 5 %, and 10 %), using polyethylene glycol (PEG) to help distribute the drug within the resin. Lower concentrations led to more even dispersion, while higher levels introduced some crystal formation but didn’t hurt performance.

In lab tests, the drug release followed a two - stage pattern: a quick release in the first 24 hours, followed by slower, sustained diffusion. At the highest concentration, about 80 % of the antibiotic was released within three days. The researchers also found that curing time during printing affected how quickly the drug was released. Longer curing times created a denser surface, slowing down the release.

The implants were tested against common pathogens including Staphylococcus aureus, Escherichia coli, and Candida albicans. All showed a clear antibacterial effect, inhibiting microbial growth by roughly 50 % within eight hours.

To test how the implants performed in a biological setting, the team exposed L929 fibroblast cells to bacterial infections. The drug - loaded implants helped the cells survive at rates similar to those seen with direct antibiotic application.

Even at full - strength extract concentrations, the implants maintained over 70 % cell viability in cytotoxicity tests, meeting ISO 10993 - 5 standards. Although one component of the resin, TPO, can be toxic in high doses, the low concentrations used and full curing process appeared to mitigate any significant risk.

While the results are promising, this study is still in its early stages. The implants haven’t been tested in living organisms yet, and more work is needed to see how they perform over time and in real - world conditions. Future research will focus on testing in animals, combining different drugs to improve healing, and finding ways to prevent antibiotic resistance.

Drug delivery through 3D printed implants offers improved control, targeted release, and patient - specific customization compared to conventional methods. While not yet mainstream, it is an emerging area of research with growing potential in fields such as cancer treatment, orthopaedics, and infection management.

In line with this, researchers at the Southwest Research Institute (SwRI) and the University of Texas at San Antonio (UTSA) developed a 3D printed implant designed to deliver a controlled dose of medication over several weeks. Made from biodegradable materials, the implant gradually dissolved after treatment, removing the need for surgical removal.